Industrial Scales vs. Regular Scales: What’s the Difference in Performance?

Industrial Scales vs. Regular Scales: What’s the Difference in Performance?

Blog Article

Everything About Industrial Scales: Trick Functions and Benefits for Your Workplace

Industrial scales are pivotal in improving functional efficiency throughout numerous markets, offering functions such as high ability, precision accuracy, and robust building. These tools not only lessen human mistake but also assist in data combination and regulative conformity, making them vital for quality control and material administration. As businesses increasingly recognize the value of these devices, the implications for performance and waste reduction come to be significantly significant. Understanding the diverse types and applications of industrial scales can offer useful understandings right into maximizing your office procedures-- yet, the trip does not end there.

Sorts Of Industrial Scales

Industrial ranges are vital tools used across numerous markets for exact weight dimension. One common kind is the platform range, which offers a large considering surface perfect for heavy and cumbersome things.

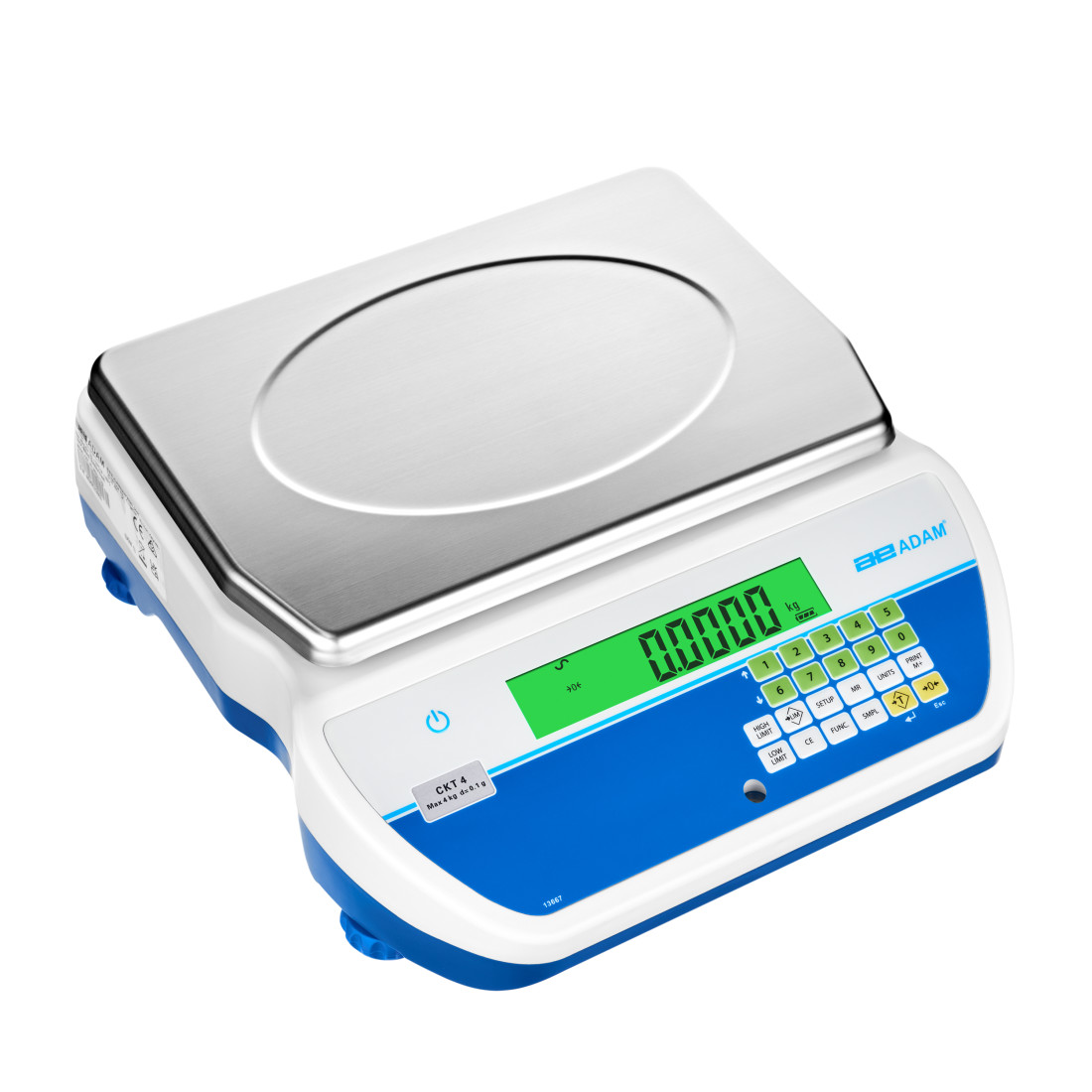

One more prevalent type is the bench scale, which is ideal and small for smaller items. These ranges are frequently located in retail and food service atmospheres, where fast and specific measurements are essential. Flooring scales offer a similar objective but are created for durable applications, permitting for the weighing of big pallets and containers straight on the ground.

Furthermore, electronic scales have actually obtained popularity due to their ease of usage and precision. They typically include advanced electronics that improve functionality, such as connectivity choices for information monitoring. Additionally, portable ranges offer versatility for on-the-go considering, making them important in areas like farming and logistics.

Understanding the various sorts of industrial scales is crucial for selecting the best devices to meet certain operational needs, ensuring efficiency and accuracy in weight dimension.

Trick Attributes of Industrial Scales

When selecting the appropriate type of commercial scale, it is very important to think about the key functions that enhance their performance and suitability for particular applications. One of the most essential features is the scale's capacity. Industrial scales are available in various weight capabilities, making sure that they can accommodate the demands of different industries, from light materials to heavy loads.

Another important feature is accuracy. High-precision tons cells are integral for guaranteeing that dimensions are dependable and regular, which is important for inventory monitoring and quality assurance. In addition, the readability of the screen plays a substantial function; clear, digital display screens with flexible brightness permit easy viewing in various lights conditions.

Sturdiness is another vital characteristic, with many industrial ranges developed to endure severe settings, consisting of exposure to wetness, chemicals, and heavy usage. Some models also feature waterproof or stainless-steel construction. Moreover, connection options such as Bluetooth or USB make it possible for seamless information transfer and integration with other systems.

Advantages for Ergonomics

Additionally, commercial ranges allow faster processing times. With automated weighing remedies, staff members can promptly get weight information without hands-on calculations, liberating time for various other crucial tasks. This velocity in operations not just enhances operational performance yet likewise helps fulfill manufacturing due dates better.

In addition, commercial scales provide beneficial data that can be assessed for constant improvement. By keeping track of weight fads, companies can identify inefficiencies in their processes and execute corrective activities, inevitably causing improved performance.

The assimilation of these scales likewise sustains compliance with sector policies, as exact reporting of weights is commonly required. This decreases the threat of costly fines and enhances the firm's track record for reliability. Industrial Scales. Generally, the incorporation of industrial ranges contributes to an extra efficient, economical, and certified workplace setting

Applications in Numerous Industries

In the food market, industrial scales are used for portion control, recipe formulation, and compliance with health regulations, assuring food safety and security and uniformity. In the visit their website pharmaceutical sector, exact evaluating is vital for drug solution, where also minor discrepancies can lead to significant governing problems and safety problems.

Building and construction and logistics sectors likewise gain from commercial scales, as they aid in handling raw materials and maximizing shipping procedures. By offering accurate weight information, these scales promote much better lots planning and conformity with transportation policies.

Additionally, the agricultural industry employs commercial ranges for weighing feed, fruit and vegetables, and animals, thus improving functional effectiveness and making sure fair trade techniques.

Upkeep and Calibration Tips

To make sure her comment is here optimum performance and durability of commercial scales, routine upkeep and calibration are necessary. A consistent maintenance routine aids identify prospective problems prior to they rise, therefore decreasing downtime and repair service expenses. Operators must routinely clean the scale to protect against debris build-up, which can affect precision (Industrial Scales). In addition, inspecting the load cells, electrical wiring, and screen for wear or damages is crucial.

Calibration is similarly crucial; it makes sure that the scale offers precise readings in accordance with industry standards. It is suggested to calibrate ranges routinely-- at least annually or more frequently if the scale is used greatly or relocated often. Comply with the maker's standards for calibration treatments, which often consist of utilizing qualified calibration weights.

Additionally, maintaining correct ecological problems, such as temperature and humidity control, can enhance range efficiency and precision. Training staff on correct use techniques will certainly additionally guard versus misuse that can lead to mistakes or damage. By sticking to these maintenance and calibration pointers, services can ensure site web their commercial scales run effectively, eventually supporting efficiency and compliance with regulative standards.

Conclusion

In summary, industrial ranges offer as vital instruments for enhancing work environment performance throughout diverse industries. By comprehending the vital features and advantages of commercial ranges, companies can leverage these tools to improve product use, decrease waste, and ultimately drive productivity.

Industrial scales are crucial in enhancing functional performance throughout different industries, offering attributes such as high ability, precision accuracy, and durable construction.When selecting the proper kind of commercial scale, it is essential to think about the essential features that enhance their functionality and suitability for particular applications. By offering precise weight dimensions, commercial ranges get rid of the capacity for human error, guaranteeing that products are evaluated constantly and exactly. It is a good idea to calibrate scales on a regular basis-- at least as soon as a year or even more often if the scale is used greatly or relocated often. By comprehending the crucial features and advantages of commercial scales, organizations can leverage these tools to enhance product usage, reduce waste, and inevitably drive efficiency.

Report this page